GEOTEXTILE FOR CONSTRUCTION

- Home

- /

- Geotextile For Construction

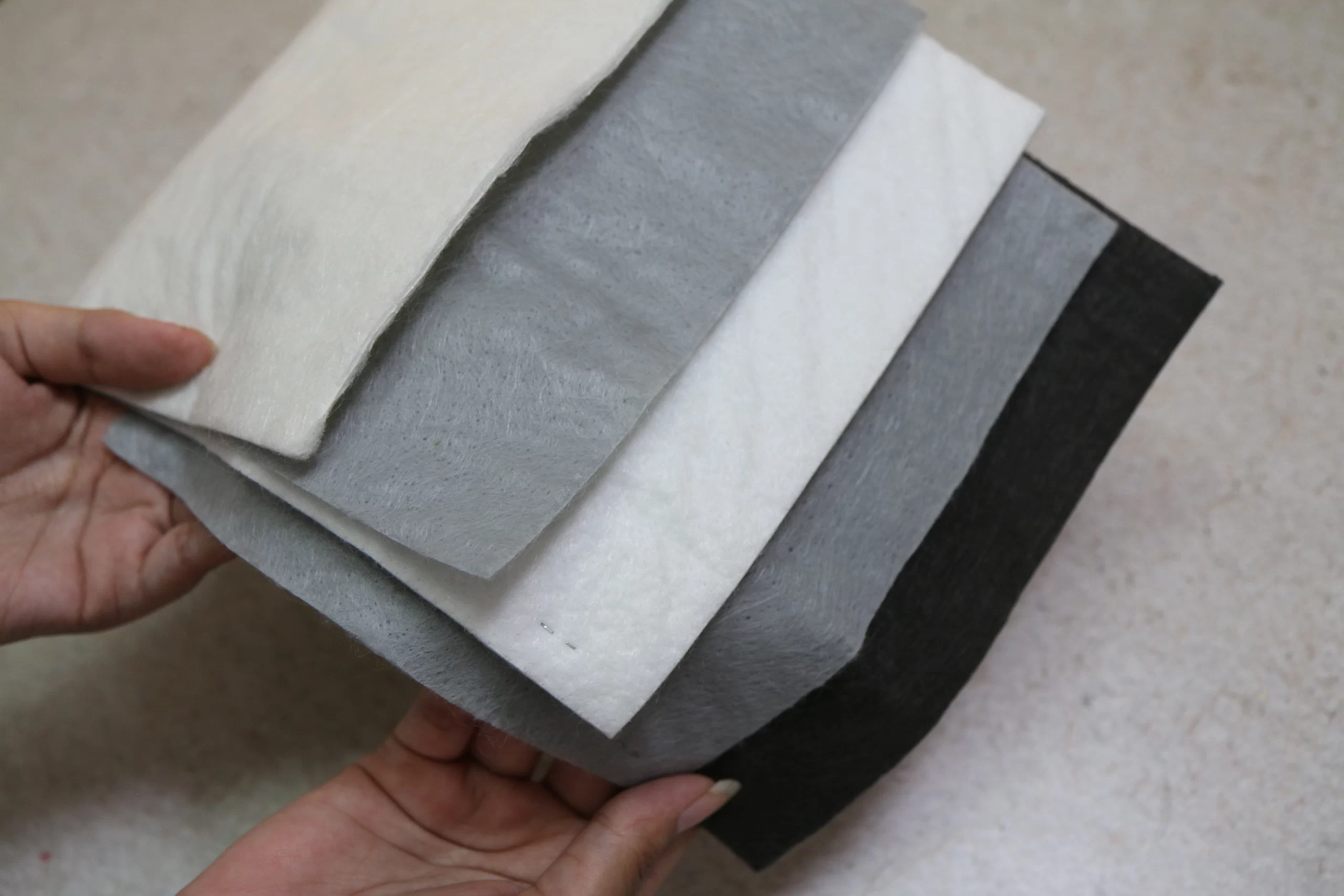

Non-woven geotextile is a type of geosynthetic material made from synthetic fibers, such as Polymer Polyester PET (Polyethylene Terephthalate), that are processed without weaving. This material is commonly used in construction projects for various purposes, such as soil stabilization, separation of soil layers, filtration, and erosion control. In construction applications, non-woven geotextile strengthens soil structures by preventing the mixing of different layers, maintaining stability, and allowing effective water drainage. Due to its flexibility, this material is well-suited for use in road construction, railway foundations, dams, and other projects that require soil reinforcement and protection. Additionally, non-woven geotextile can be made from recycled PET (Polyethylene Terephthalate), contributing to sustainability efforts in construction practices.

Non Woven Geotextile Fabric provide numerous advantages and benefits when used in construction projects. These versatile materials are key components in civil engineering applications, offering several functional, environmental, and economic benefits. Here are some of the key advantages and benefits of using non-woven geotextiles in construction:

- Separation

- Reinforcement

- Filtration

- Drainage

- Erosion Control

Non-woven Geotextile Fabric are typically designed to withstand various weather conditions and exposure to ultraviolet (UV) rays for a certain period. This material can endure hot, cold, dry, or wet conditions and remain effective in diverse environments and climates.

What is non-woven geotextile fabric for?

Non-woven geotextile fabric is a versatile material used in various construction, landscaping, and environmental applications. It is primarily designed for:

- Drainage: Allows water to pass through while filtering out soil and other particles, making it ideal for drainage systems like French drains.

- Erosion control: Stabilizes soil on slopes, embankments, or around water bodies, preventing erosion while maintaining water flow.

- Soil stabilization: Separates soil layers in road construction or foundations to improve stability and prevent shifting.

- Weed control: Acts as a barrier in landscaping to block weeds while allowing water and nutrients to reach plants.

- Filtration: Used in projects where water filtration is needed, such as retaining walls and drainage systems.

Its strength, permeability, and durability make non-woven geotextile fabric essential in many civil engineering and landscaping projects.

What is non-woven fabric construction?

Non-woven fabric construction involves creating fabric directly from fibers, without the traditional weaving or knitting processes. In this method, fibers are bonded together using techniques such as heat, chemicals, or mechanical processes, forming a fabric that is flexible, durable, and lightweight. Non-woven fabrics are often used in a variety of applications, including construction, medical products, packaging, and geotextiles.

For construction purposes, non-woven fabrics are used in areas like drainage, soil stabilization, and erosion control. Their ability to allow water to pass through while maintaining strength and durability makes them ideal for these uses. The versatility of non-woven fabrics makes them a popular choice for many industrial and commercial applications.

Which is better, woven or non woven geotextile?

Whether woven or non-woven geotextile is better depends on the specific application:

Woven Geotextile: It is made by weaving fibers together, resulting in a strong and durable fabric with high tensile strength. This makes it ideal for applications where soil stabilization and load distribution are essential, such as in road construction and embankment support.

Non-Woven Geotextile: It is made by bonding fibers through heat, chemicals, or mechanical processes. Non-woven geotextiles are more flexible and permeable, making them better for drainage, filtration, and erosion control, where water needs to pass through.

Does geotextile fabric stop water?

No, geotextile fabric does not stop water. Most geotextile fabrics, especially non-woven types, are designed to be permeable, allowing water to pass through while filtering out soil and debris. This makes them ideal for drainage, erosion control, and soil stabilization, where water needs to flow freely but solid particles need to be retained. However, if you’re looking to prevent water movement, you would need a different type of barrier material, like a geomembrane, which is impermeable.

Is non-woven fabric waterproof or not?

Non-woven fabric can be either waterproof or non-waterproof, depending on how it is manufactured. Some non-woven fabrics are treated with special coatings or made from water-resistant materials, making them waterproof. These are often used in applications like medical products, packaging, and protective covers. However, many non-woven fabrics, especially those used in geotextiles, are designed to be permeable, allowing water to pass through while filtering out particles. These types of non-woven fabrics are not waterproof but are ideal for drainage and filtration purposes. So, whether a non-woven fabric is waterproof or not depends on its specific design and intended use.